| Build Thread, Page :

1 2 3 4 5 [ 6 ] 7 8 9 10 11 (223 posts, 20 posts per page, 12 pages in total)

|

[ < Prev ] [ Next > ] |

| frwyflyer, Comment for image # 14373 | 06 Oct 09 11:56 |

| I heartily second Mr. Duckett's comment. |

| David Duckett, Comment for image # 14373 | 06 Oct 09 11:42 |

| Amazing!!! |

| pfinn, Comment for image # 14373 | 06 Oct 09 09:07 |

| Sorry, Prop Hub Dia. is .900" (for a big B-29 that's been frequenting these pages lately, and the gear are for the 1/24 scale Diels Engineering Tigercat. |

| dgreg, Comment for image # 14373 | 06 Oct 09 01:56 |

| Well done.. What is the diameter of the prop hub??.. it is difficult to scale without a reference.. Thanks |

| pfinn, Image # 14373 | 06 Oct 09 01:11 |

Happy parts. |

| BillParker, Comment for image # 13345 | 05 Oct 09 17:08 |

| Oh that's just amazing! If I had half that kid's ability...

wow! Be proud. man... |

| pfinn, Comment for image # 13345 | 05 Oct 09 16:46 |

| Here's a short clip of Jimmy flying http://www.youtube.com/watch?v=dpHv5AiGe7A |

| frwyflyer, Comment for image # 14230 | 28 Sep 09 16:21 |

| WOW! This little guy does everything it can to keep off the ground and keep in the air. Amazing |

| pfinn, Comment for image # 14230 | 28 Sep 09 15:55 |

| Luckily on the last one with a good launch, I launched into sink. It would have been on the roof had it been in "Good" air. Name and phone number is going on next! |

| David Duckett, Comment for image # 14230 | 28 Sep 09 15:24 |

| Sweet!! I'm amazed it flys so long! |

| rhysleo, Comment for image # 14230 | 28 Sep 09 15:21 |

| wow! that goes high for a little glider. did you ever get it back after it going on the roof?

|

| pfinn, Image # 14230 | 28 Sep 09 14:57 |

I'm trying a video link. |

| SteveM, Comment for image # 13989 | 08 Sep 09 12:56 |

| Very nice castings! Thank you for sharing your technique. |

| David Duckett, Comment for image # 13989 | 08 Sep 09 03:27 |

| "Moist" just isn't an adequate description!! |

| pfinn, Image # 13989 | 08 Sep 09 02:53 |

Fresh out of the mold. |

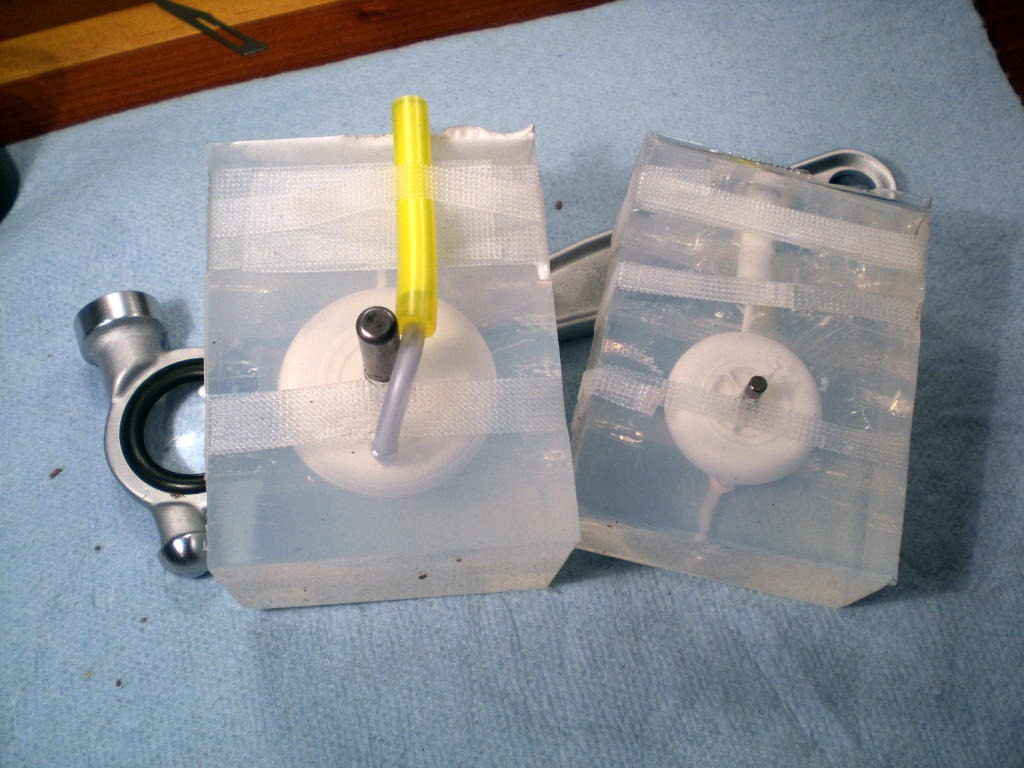

| pfinn, Image # 13988 | 08 Sep 09 02:51 |

"Look Ma, no "Flashing"!" |

| pfinn, Image # 13987 | 08 Sep 09 02:48 |

Pulled them out of the pot after about 30 min. still have to wait at least another 30 min. to demold. The waiting game. Tic Toc...Tic Toc. Don't remove too early, They will deform. |

| pfinn, Image # 13986 | 08 Sep 09 02:43 |

Another must for proper castings. After injecting resin into th molds (Gotta work fast, this stuff has a 2 minute working time!), immediately place in a pressure pot at about 80 psi (pressure pots' limit). This step gets " The liquid resin into all the nooks and crannies"! |

| pfinn, Image # 13985 | 08 Sep 09 02:36 |

Ready to cast. I recieved this urethane resin from DD. Very thin withou too much shrinkage. I "Like" it. The 3m Flexi Bandage tape worked out well to hold the mold halves together. Rip off a length then tear strips off at desired width. 1/4", 1/8", no.problem. This replaced the rubber bands I forgot. Glad I did, the tape worked much better! Another "Fortunate Mistake". |

| pfinn, Image # 13984 | 08 Sep 09 02:26 |

Plunge cut a Zig-Zag pattern for the outer edges (for registering the mold halves) with a chisel point blade. A sharp no.11 to the pattern. This is one way to do the parting. It's much quicker than making two separate halves with two mold castings. Ugly as sin but it does yield excellent results with an almost invisible part line. |

| Build Thread, Page :

1 2 3 4 5 [ 6 ] 7 8 9 10 11 (223 posts, 20 posts per page, 12 pages in total)

|

[ < Prev ] [ Next > ] |