| Build Thread, Page :

<< 2 3 4 5 6 [ 7 ] (136 posts, 20 posts per page, 7 pages in total)

|

[ < Prev ] |

| kenm94591, Comment for image # 41845 | 12 Feb 20 18:41 |

| Thanks for the answer. My next project is a scratch build, kind of. I have the plans w/o parts. |

| edtherenderman, Comment for image # 41845 | 12 Feb 20 12:17 |

| Not planning on flying. Going heavy scale again. I do need to look at flying options though. Pacific North West weather will start getting nice again in about six months. We had 34 days of rain in the first 38 days of the year! Been really wet! |

| bsadonkill, Comment for image # 41845 | 12 Feb 20 12:06 |

| Wow, a $250 laser cutter. Looks like it did just fine. I sold my 650 B.S.A. two years ago. Will this one fly? |

| edtherenderman, Comment for image # 41845 | 12 Feb 20 08:19 |

| It’s a good question! The way I’ve gone with this rig, it would be difficult. It is doable, and I think I have a good pipeline now, but for someone who doesn’t enjoy the continuous challenges that computer provide, it may not be the way to go.

However, there are more expensive, all-in-one laser etchers out there. A work mate of mine has a Glowforge printer (https://glowforge.com/). This printer has a much higher powered laser, so less passes to cut each piece, and software that is able to scan a line drawing or photograph and create the files needed to do the etching. He hasn’t tried that technique with his so I have no firsthand experience on how well it works. Knowing what I know, I’d wonder how precise the part would be. It would require a very clean drawing to begin with. I thought about this option, but the $2500 price tag put me off. That’s why I went with the $250 option, then spent about a week of evenings, and one full 1/16 x 6 x 36 balsa test sheet to figure out how to make things work!

The good news is that this market, like 3D printing, is growing and more demand means more features at lower cost. Technology that is $2500 today will be $500 in just a couple of years.

|

| kenm94591, Comment for image # 41845 | 11 Feb 20 21:29 |

| That really looks interesting but I am wondering how difficult it is to use the software for someone who just barely uses the computer. |

| BriandKilby, Comment for image # 41845 | 11 Feb 20 10:01 |

| that is so cool! |

| edtherenderman, Comment for image # 41844 | 10 Feb 20 12:17 |

| Outerzone rocks! I have about 30 plans I want to scratch-build now. The laser does cut through if you have enough passes. Mine takes six passes for fairly dense 1/16” sheets. About 30% of the parts cut through. The rest are held by just a few fibers. Easy to remove with a sharp blade. A lot depends on the consistency of the sheet. I'd say that the cuts are better than the die-cut parts you find in Guillows kits. Much cleaner, and no crushed edges or broken tabs!

Thanks for the interest in the Jaguar. Check out https:\\leapingv8s.blogspot.com. Contains 200 posts of my 10 year project of restomoding the car.

|

| edbecky, Comment for image # 41844 | 10 Feb 20 11:38 |

| I really like Outerzone. Working on a Zero from plans off OZ now. The laser looks interesting. Does it cut so the parts can be easily removed? Also would like to see more pics of the Jaguar. I sold my MB 300CD but that's another story. |

| Don C, Comment for image # 41846 | 10 Feb 20 10:05 |

| I like that idea. My fingers were cramping yesterday from cutting ribs and notches. |

| edtherenderman, Comment for image # 41848 | 10 Feb 20 09:02 |

| The rudder fin and bottom stabilizer are sheeted and faired into the fuse, so I needed to get them done before I start the sheeting of the fuse. |

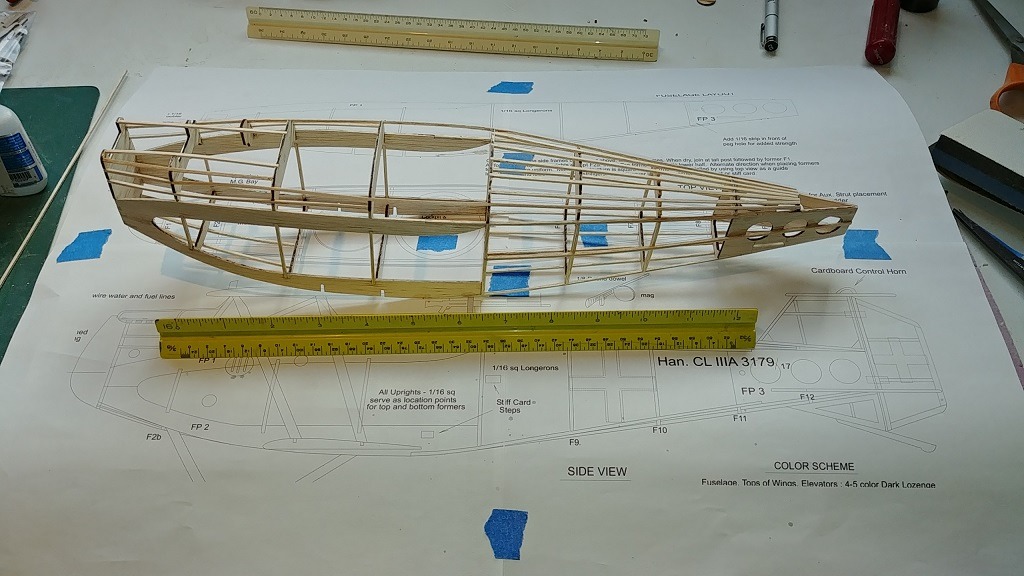

| edtherenderman, Comment for image # 41847 | 10 Feb 20 08:54 |

| The Hannover had a sheeted fuse, like the Albatross, Pfalz, Roland, etc. I’m planning on sheeting this fuse, but before I do, I’m going to decide how much detail I want to put into the engine and cockpits. Since this is such a large model, I have a lot of room to go crazy with detail. I’m thinking of 3D printing a full scale engine for this, as well as interior details. Still haven’t made up my mind though. |

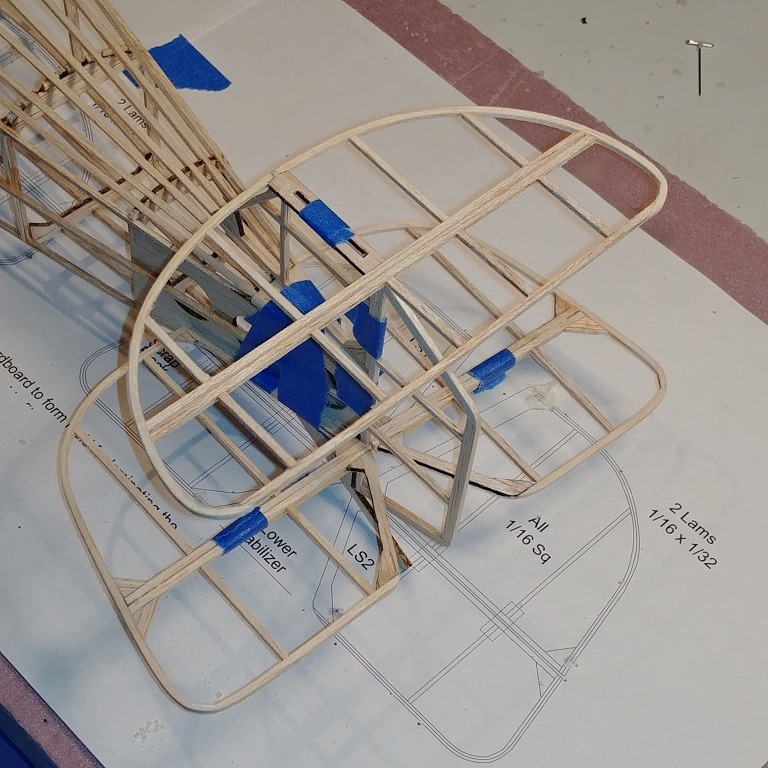

| edtherenderman, Image # 41848 | 10 Feb 20 08:50 |

Also rough formed the empennage. The Hannover is unique having two horizontal stabilizers. The idea was that it would improve Gunner/observers arch of fire since the stab could be smaller. I think it makes a cool looking aircraft! |

| edtherenderman, Image # 41847 | 10 Feb 20 08:48 |

Fuse together. Standard box build technique: Build both sides on the plans, glue the tail post, tape the first former on, than carefully glue in the top and bottom formers. This is going to be a big airplane. It’s 1/16 scale so around 30” wingspan. I was going to downscale it to 1/20, but because I was also dealing with the Laser Etcher, I decided to go with the larger scale. |

| edtherenderman, Image # 41846 | 10 Feb 20 08:43 |

Fuse parts cut! It took about 1.5 hours to cut the parts. With a more powerful laser, the time would go way down since it takes 6 passes for each part. The more time consuming part is converting the drawing into a file the etcher can use! If anyone is interested in this method, let me know. I’m happy to talk about my pipeline. I was able to cut all the parts for the airplane on one 1/16 x 6 x 36 sheet of balsa, including twice as many wing ribs as outlined in the plan. I was cutting for a good 8 hours, but once I was comfortable that I wasn’t going to catch anything on fire, I was able to do other work while the cutting happed. It’s still a good idea to keep your eye on it though! |

| edtherenderman, Image # 41845 | 10 Feb 20 08:38 |

Here is the laser cutting the second part. This is 1/16 sheet, 6” wide. I realize this picture may be a bit misleading. The little hose with the fitting on the end looks like the source of the laser. It’s actually an airbrush hose used to blow low pressure air on the work surface. The air keeps the smoke from diffusing the laser, fogging up the laser lens, and puts out any small sparks that may end in a burned up piece of balsa and small garage fire! |

| edtherenderman, Image # 41844 | 10 Feb 20 08:34 |

Started work this weekend on the Aero-Werkes Hannover CL IIIa. I’m scratch building it from plans I found on Outerzone (https://outerzone.co.uk/plan_details.asp?ID=1156). This is my first attempt at using a $250 2D Laser Etcher/Cutter that I got off of Amazon to cut the balsa parts. Here is my rig. Cutter on the left, laptop on the right, ’71 Jaguar in the background |

| Build Thread, Page :

<< 2 3 4 5 6 [ 7 ] (136 posts, 20 posts per page, 7 pages in total)

|

[ < Prev ] |